An innovative 3-D inkjet printing method has allowed researchers from the University of Sheffield to take the biggest step yet in producing microscopic silk swimming devices that are biodegradable and harmless to a biological system. These devices will potentially be used in the human body for applications including drug delivery and to help pinpoint cancer cells.

Previous devices have been expensive to produce, complicated to manufacture and made from polystyrene beads, carbon nanotubes or metals which have to be covered in a catalyst layer (such as platinum) to be able to swim successfully. These devices are often unfriendly to the biological environment they are placed in. Using this new technique, however, researchers will be able to use safer, non-toxic materials which will not cause harm to or injure any living tissue or biological environment.

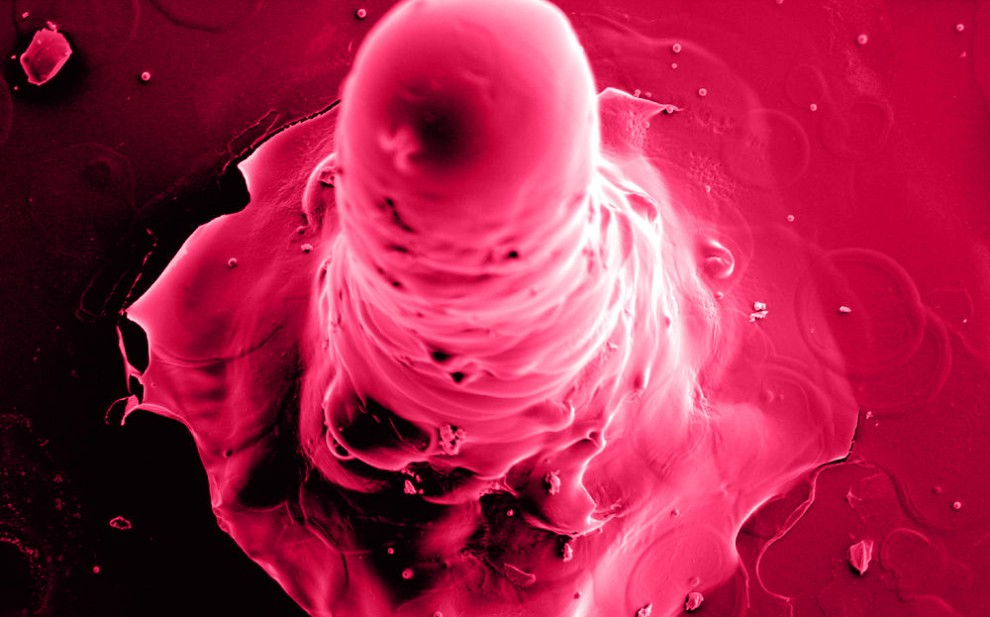

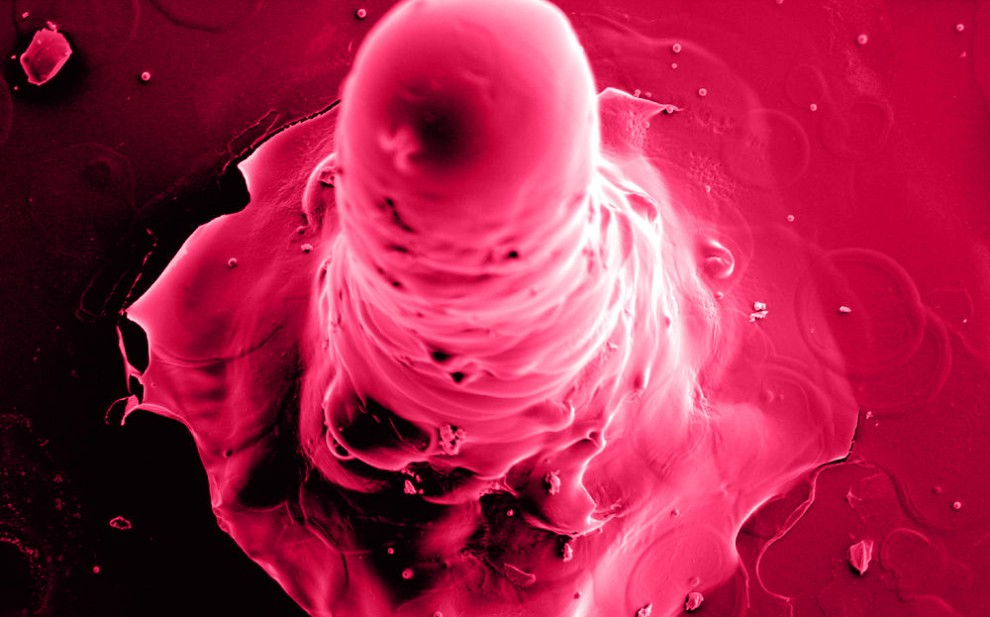

The size of a single rocket is miniscule, 300 microns in length and 100 microns in diameter, which can be comparative to the thickness of a single human hair and to top it off they create their own thrust, allowing them to swim through any bio fluid containing the fuel.

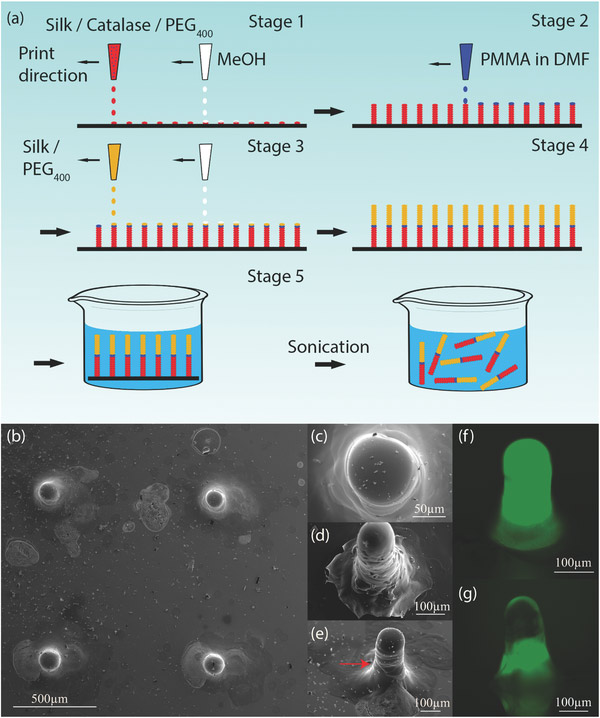

This is the first time these micro-rockets have been produced using this new reactive inkjet printing method, which uses a solution of dissolved silk mixed with an enzyme. This solution is placed into a 3-D inkjet printer, which, in a process is similar to normal inkjet printing, builds up layers of ink to create a column of the rocket.

By printing methanol on top of the printed solution a reaction is triggered which forms rigid rocket shape, trapping the enzyme within a silk lattice structure. Enzyme operates as a catalyst, reacting with fuel molecules to produce bubbles that propel the rocket forward.

Using an enzyme as a catalyst and silk to form the rocket produces a much safer device that is biodegradable, cheaper and simpler to make, removing a major barrier to micro-rockets becoming a reality outside of the lab.

The inkjet printing technique also allows to digitally define the shape of a rocket before its placed in the production. This makes it a lot easier to optimize the shape in order to control the way the device swims through the system.

The full study was published in the Small journal.