3-D printer uses power of light to create terahertz lens. Newly developed lens could be used for security imaging and biomedical research.

Terahertz is a wavelength within the electromagnetic spectrum that is neither well understood nor often discussed, although it does play a very important role in both imaging and communications. Cheng Sun from Northwestern Engineering called terahertz a gap between microwaves and infrared. He says people are trying to find a better understanding of this wavelength because it holds a lot of very important information.

Along with his team, Sun has combined metamaterials and 3D printing in order to build a contemporary lens that uses terahertz frequencies. The lens creates better imaging possibilities than regular lenses and is leading the way for better advancements in the world of the misunderstood wavelength and may be applied in the biomedical field as well as for security imaging. The team posted their findings in the April 22nd issue of Advanced Optical Materials journal with help by the National Science Foundation.

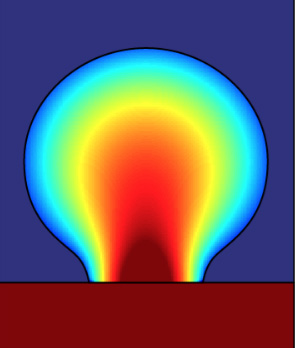

Sun, who is currently an associate professor of mechanical engineering, says that typical lenses even very high quality ones have a number of different pieces in order to cancel out imperfections. This means, in order to provide an optimal image there has to be a stack of systems which can prove to not only be very expensive, but also very complicated. Typical lenses have focal lengths that are determined by both the curvature and the refractive index which bends light. Without all the extensive layers to counteract natural imperfections, you would find a very low quality picture. Sun’s lens does not require corrective components, but uses a gradient index that changes over the space it inhabits, offering a high quality image.

This new lens works because it is made from a metamaterial that offers properties that cannot be found within nature. These properties are much smaller than the terahertz wavelength according to Fan Zhou, a member of Sun’s laboratory. He says by assembling these structures, a very specific refractive index distribution can be created. With the help of a 3D printing technique known as projection micro-stereo-lithography, researchers are able to organize metamaterials to fit the exact designs they were going for at a very low cost.

Sun’s team uses a liquid photo-polymer to print THz lenses. When the material is exposed to light, it takes a solid form in the shape of the light being shined on it. This is what creates the 3D structure. What is most exciting about this lens is that it will make terahertz imaging more readily available. This imaging will help create better security at a much cheaper price with the promise of a much higher quality images. Unlike standard X-Ray machines used today, terahertz scanners are able to detect plastics and chemicals. This would help locate concealed weapons and chemical weaponry, as well as cause less damage to the human body, since these new scanners do not give off harmful radiation.

Wei Cao, a collaborator of Sun’s from Oklahoma State University says this advancement opens up a whole new source of information with a wide range of helpful uses in both the biomedical field and security. Studies continue as researchers try to get a deeper understanding of exactly what terahertz are capable of doing in the world of science and technology.